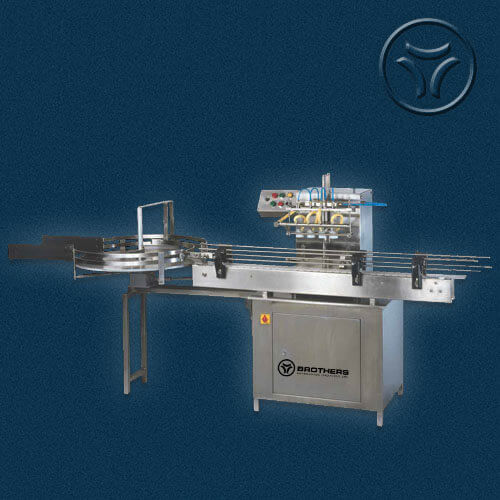

The Automatic Eight Head Twin Track Air Jet Cleaning Machine Model AIRWASH-200 with speed of Max. 150 bottles per minute depending on Bottle Diameter, Height and Bottle Neck Diameter.

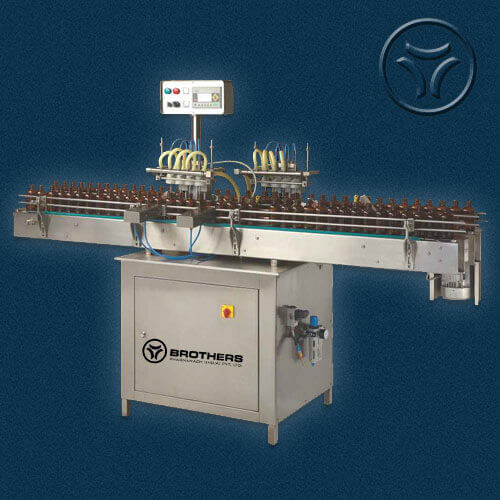

Machine with specially designed Twin Track Bottle Movement System producing higher output by handling linear bottle movement at lower speed resulting in smoother movement of bottle. Twin track system is ideal for handling bottles at lower speed but giving higher output where the linear movement of bottle is not easy at higher speed due to lesser diameter and more height of bottles. The Air Jet Cleaning Machine applies Compressed Air through Jets and also sucks through Vacuum. Machine can be used to clean Glass/Plastic/PET Bottles, Jars etc. Machine suitable for cleaning of non-sterile products like Dry Syrups, and Bulk Packing of Tables and Capsules.

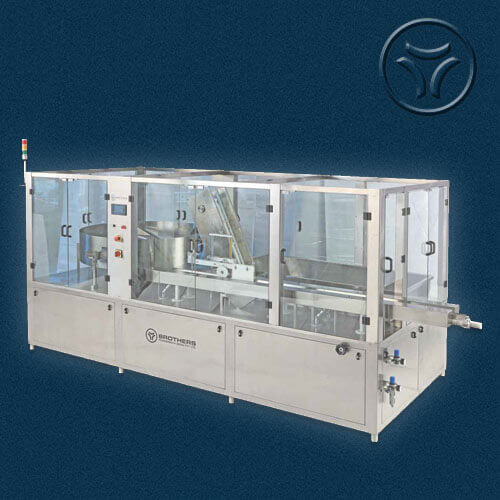

Machine with built-in Turn Table which feeds container in vertical position and deliver to both the track of machine conveyor. Further bottles move towards cleaning station, where cleaning heads grip the container through cup holder and starts the Compressed Air and then Vacuum to clean the bottles.

Machine in Stainless Steel Finish with all contact parts in S.S.316 and Nylon Material. Machine also having overload clutch system to prevent jamming during the operation. The manifold comprises of inner nozzles which jets compressed air in the bottle and an outer socket, which cover the mouth of the bottle and is connected to an exhaust, ensures perfect cleaning.